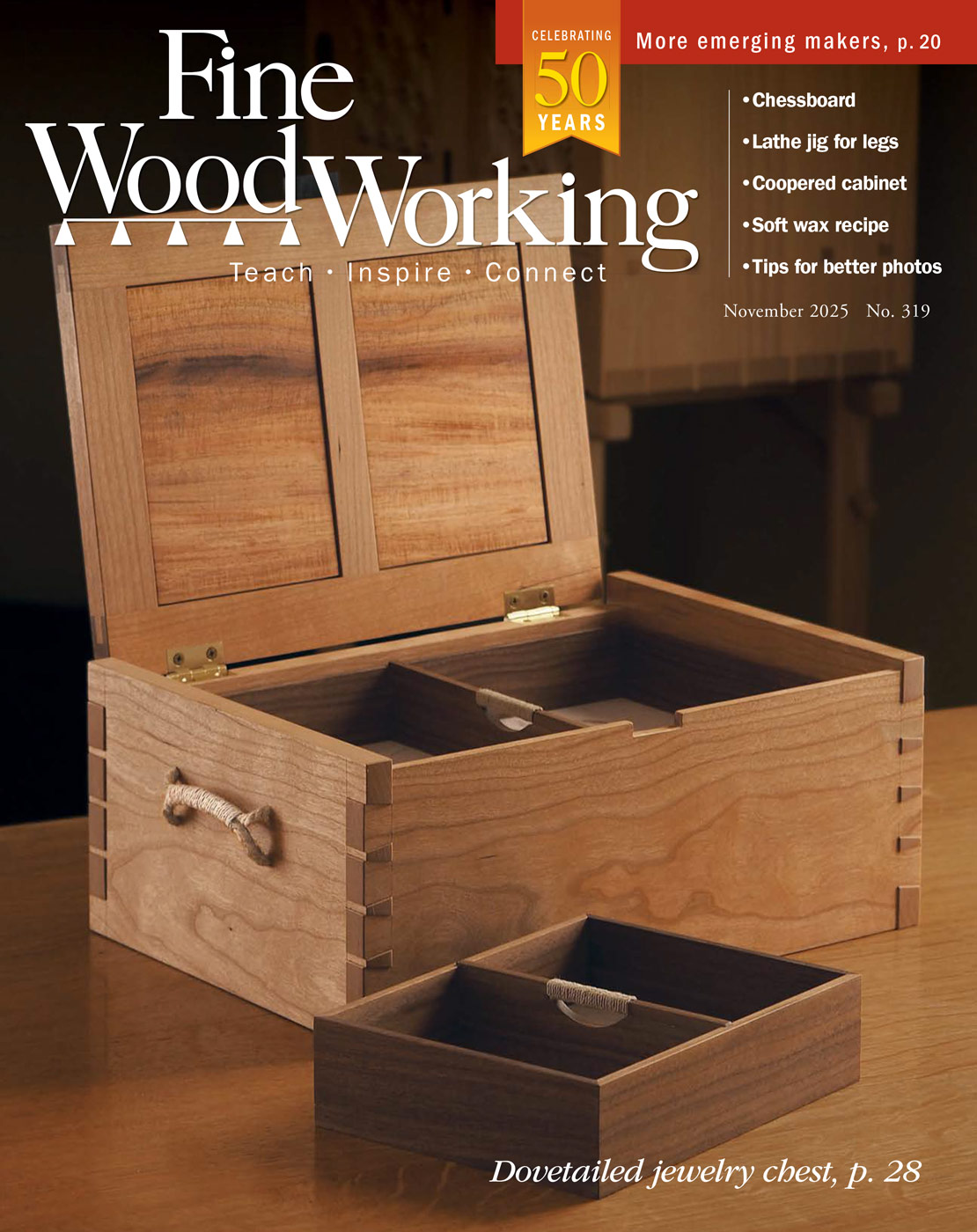

From the Editor: Setting Up for Better Work

Making your shop work for you is no easy task, but our annual Tools and Shops issue can help carve the path

A big challenge in woodworking is that there are so many critical aspects to consider before we can actually get to work. Our annual Tools & Shops issue offers an opportunity to take a step back from building things and look at the state of our tools and the places we call our shops. From there we can chart a course toward doing better work and finding more enjoyment in the time we spend in those shops.

While most of us would like to have a bigger space to work in, our ability to adapt the space we have can make a bigger impact on our enjoyment and productivity than increasing the square footage. In this issue, Alan McIvor shares his ingenious strategies for getting

the most from his single-car garage shop, with tips from layout to storage solutions that make the most of the space he has to work with. Regardless of the size of your shop, I’m confident there will be many ideas that you can put to use as well.

When our results don’t match our intentions, we tend to blame our lack of skill or experience, but the reason for our troubles can often be attributed to the condition of our tools or machines. Following his review of mid-size lathes in FWW #307, Andrew Finnigan suggests in this issue some lathe upgrades that can help turn a solid tool into a top-rate performer. And on the subject of tuning-up tools, Mark Harrell presents a valuable primer on getting a vintage backsaw up and running.

Setting up a shop can involve a big financial investment, and gathering all the machines on our shopping lists can take a long time. This doesn’t mean that we need to wait until we have everything in place, or limit what we make. Vic Tesolin illustrates how to get by just fine without that shop cornerstone, the table saw. Not only can you do good work without one, but you may find you can skip that purchase altogether.

While often overlooked, sandpaper is a staple in just about every shop, and it often plays a leading role in finishing a project. Adam Godet dives into the world of coated abrasives and offers insights into the factors involved in choosing the right product for the job. Whether you’re sanding by hand or machine, the right grit, coating, and backing can make faster work of the task and offer better results. From sandpaper to backsaws, machine upgrades to shop layout strategies, I’m confident that this issue will help you to get set up in your shop, have more fun when you’re there, and achieve the results you want.

Comments

Greetings from Northern Michigan! I’m renovating my barn loft into my new woodshop and I’m wrestling with what type of heater would be best to install. The area is 800 sqft. I’ve an air filtration system from Grizzly that hangs from the ceiling to filter out dust particles. My main equipment dust collector is in the downstairs main floor of the barn so all the dust collection attached to all equipment is being piped downstairs to it. My main concern is if I use a portable heater that has a fan to distribute the heat throughout my woodshop that it’ll still blow dust particles that’ll get into my wood finishes. If I go with the hanging infrared type heaters I feel that I’d be wasting heat up at the ceiling and take longer to heat the whole shop which is well insulated R20 ceiling and walls. Thank you in advance!

Log in or create an account to post a comment.

Sign up Log in