Why You’ll Always Need More Wood Than You Think

Vic accounts for waste and milling when buying lumber, and you should too.

Let me tell you something that might break a few beginner woodworkers’ hearts: If you think you can calculate the exact amount of wood you’ll need for a project, buy it, and be done, you’re living in a fantasy world—and not the good kind with elves and mead halls. I’m talking the kind where everything should work out perfectly—but somehow never does.

Here’s the reality: You will always need more wood than you think. Always.

I’m not just saying that to pad the lumber industry’s profits. I’m saying it because after years of building furniture, cabinets, and the occasional questionable “What was I thinking?” project, I’ve learned that 25% to 30% extra wood isn’t a luxury—it’s a survival tactic.

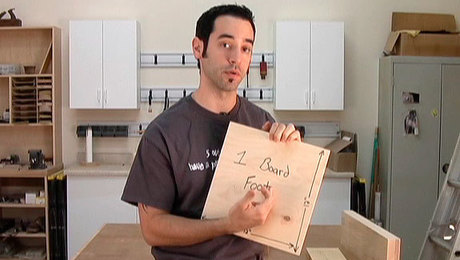

The Myth of the Perfect Board-Foot Calculation

Board footage is a great tool for one thing: estimating cost. It’s how you figure out what you’ll pay at the lumber store. But as far as predicting how much material you’ll actually have when you’re ready to start cutting? Forget it.

Here’s why: Milling operations eat wood. Every time you joint a face, plane a board, or trim an edge to square it up, you’re removing material. And that’s before you consider the sneaky thief known as grain selection.

Grain Selection: The Beautiful, Wasteful Truth

Grain selection is the process of picking which parts of the board will be visible in your final project. This is how you get your work to look like it came from a craftsperson’s shop instead of a factory assembly line.

The problem? When you’re matching grain patterns or avoiding knots, checks, or other defects, you end up cutting around the bad bits. And those cutoffs are rarely big enough to use for anything more than shop jigs, wedges, or that one “future project” pile we all keep and never touch.

If you skip grain selection, sure, you’ll save a few bucks. But you’ll also end up with a piece that looks like it was made on a Monday morning in a furniture factory where the coffee machine was broken.

My Lumber-Buying Strategy

When I’m planning a project, I estimate the wood I’ll need as if the world were perfect—no defects, no mistakes, no planing down a warped board. Then I add 25% to 30% more. That’s my real number for budgeting.

After that, I head to the lumber store and start choosing boards one by one. I’m looking for straightness, width, thickness, and—most importantly—grain and color that will make the project shine. Inevitably, I’ll find boards that work perfectly in some areas but will require me to cut around a wonky knot or a wild grain swirl in others. That’s when having that buffer pays off.

Think of that extra wood as insurance. It’s there to cover mistakes, account for milling losses, and give you the freedom to choose the most beautiful grain for your project. And if you somehow end up with leftovers? Congratulations! You’ve just started your stash for the next build.

In woodworking, too much wood isn’t a problem. It’s a blessing.

Honestly, if your workshop isn’t at least 15% made of leftover boards, are you even a woodworker? And everyone needs cutting boards, right?

Fine Woodworking Recommended Products

Ridgid R4331 Planer

DeWalt 735X Planer

AnchorSeal Log and Lumber End-Grain Sealer

Log in or create an account to post a comment.

Sign up Log in