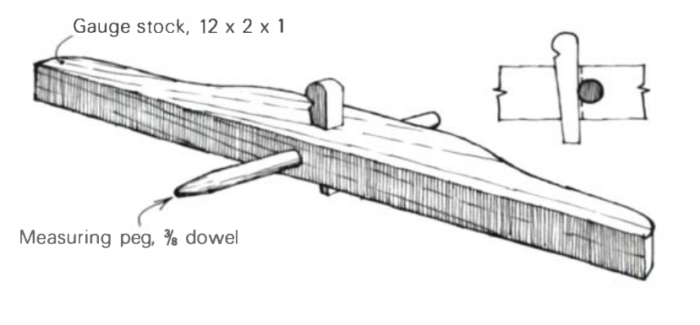

Inexpensive shop-made bowl turning depth gauge

This DIY jig is easy to both make and use

When turning a hollow, as for a bowl, it is difficult to estimate how deep a cut has been taken. Although the best curves may be made by eye, it is necessary to know the depth to check on the remaining thickness of wood and avoid turning through. A ruler can be held against a straightedge across the rim of the bowl, but that is an improvisation. The tool described here is a more efficient way to check depth.

Make the stock wide enough to span the largest-diameter bowl your lathe can turn. The base must be flat. The other parts can be shaped as you wish, but edges should be rounded for a comfortable grip. It is easier to get the peg hole perpendicular to the base before other shaping is done. The wedge hole can be cut at the same time.

The peg may be a length of dowel rod. Its working end should be slightly tapered and finished with a little doming where it will touch the bowl.

The slot for the wedge has to be made with its edge cutting through the peg hole by a small amount, so pushing the wedge in tightens it against the peg. An overlap of should be enough. Make the wedge and measure the thickness of the stock centrally on it. From the distance across the wedge at these points, mark the width of the hole at each side. The ends of the wedge can be rounded and decorated, but a plain wedge works just as well.

Fine Woodworking Recommended Products

CrushGrind Pepper Mill Mechanism

Log in or create an account to post a comment.

Sign up Log in