STL347: Don’t Reinvent the Bench

Ben, Amanda, and Owen catch up about our dream shops, what we would go back and change, and what's okay being left alone.Owen’s Cool New Shop:

Owen’s Smooth Move:

Owen chatted a bit about his recent experience with a router table, and how he might pivot to a dado stack.

Cameron:

Hoping for a bit of advice here. I’m planning on building my first workbench. While I love the Festool MFT, it’s just not large or sturdy enough for me. My plan is instead to start with a “traditional” workbench capable of handling hand work, and add some MFT functions including 20mm hole grid on the top and rail hinge supported by extruded T-slot rails front and back.

I’ve located most of the necessary components (UJK Parf system, Dashboard Rail Guide, McMaster 1530 rail, etc) but I’m just left with figuring out what bench design to base this all off of. I’m light on skill and I don’t want to spend too much time or money on building the bench as I haven’t yet had a chance to learn what actually works for me in terms of bench design.

Any thoughts?

You can buy plans or a flat pack version of the Paulk Workbench here.

Every two weeks, a team of Fine Woodworking staffers answers questions from readers on Shop Talk Live, Fine Woodworking‘s biweekly podcast. Send your woodworking questions to [email protected] for consideration in the regular broadcast! Our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page. Join us on our Discord server here.

Comments

Shop bench thoughts... In reference to the question about novice woodworker wanting to build first bench. Super easy to find thick, flat enough butcher block tops for purchase so you don't have to waste valuable short time gluing up and flattening a top. - got mine 2-1/2" thick by 30" wide by 72" long, perfect for me... Festool MFT clamps will only work on tables that are a maximum of about 20mm (0.8") so cannot really make a thick solid wood worktop with Festool grid style holes and use Festool style clamps.

What happened to Phil Morley's shop?

@cameron — I heard the podcast and thought I might be able to help. First of all, the Fine Woodworking hosts are wonderful, but I disagree with their recommendation to build the Paulk Bench. I agree with Ben that Vic Teslin would have been a better choice to answer your question. That said, I think I can offer you another solution worth considering.

⸻

Why not the Paulk Bench?

Ron Paulk designed his bench as a large, portable assembly table he could leave on-site at a client’s location, avoiding the cost of multiple MFTs. While it’s clever for that purpose, here’s why I wouldn’t recommend it for your needs:

• Bulky – Takes up a lot of space and is awkward to store.

• No storage – Everything has to be stored separately.

• Not ideal for hand tools – It’s fine for sheet goods (so is the MFT/3) but lacks the weight and stability to resist lateral movement when hand planing.

For hand tool work, a bench needs to be heavy and rock-solid.

⸻

My setup

I use a Bora Centipede 4×6 with three folding 20 mm hole tops and storage bags. When breaking down sheet goods, I can use all my MFT/3 accessories on it. When done, it folds into a compact package.

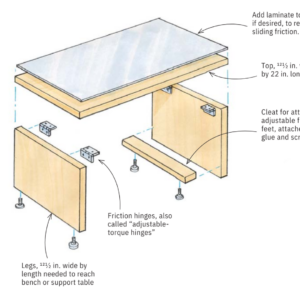

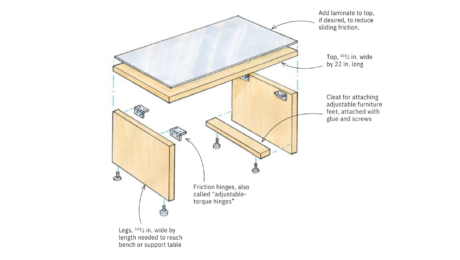

My main bench is still an MFT/3 mounted on a Festool-designed cart (I’ve even seen the same cart in Vic Teslin’s shop). Plans here:

https://www.festoolusa.com/-/media/tts/fcp/festool-usa/downloads/buildseries/build-series-4-layout.pdf

⸻

Modifications I made

1. Custom dimensions – Sized to fit my systainer drawers (three sections) plus a CT Midi on one side. Used only 2 sheets of plywood

2. Height adjustment – MFT/3 also serves as an outfeed table for my SawStop.

3. Materials – Quality plywood from a big-box store (no fancy Baltic birch) with oak trim.

4. Mobility handle – Added a thick shower safety rail to push/pull the cart.

5. Casters – Swapped for self-levelling casters so the bench is rock solid when parked.

⸻

Why it works better

• Stability for hand tools – Doesn’t move during planing or dovetailing.

• Clamp flexibility – MFT rails allow horizontal clamping for joinery work.

• Support for long boards – Domino holes help secure stock when planing.

• Integrated storage – Keeps tools organised and accessible.

• Looks good – Presentable enough to be proud of in the shop.

Ps if you don’t have the mft3 table, it is worth considering, or you can make your custom top out of mdf.

⸻

Best of luck with your setup

For clarification, I specifically didn't have Vic answer it because he's answered it many times in various ways in a few episodes.

Ben, I got the Milwaukee M12 electric screwdriver and liked it so much that I bought 2 more M12 tools. The M12 subcompact drill/driver is now my go to tool. It is not as fast or powerful as my larger d/d but as you said in the STL the slower speed is kind of a nice change. Both the screw and drill drivers will fit in a apron or tool belt pocket so they aren't banging into things or my leg.

Log in or create an account to post a comment.

Sign up Log in